wishbone “split” seat tubes

The split seat tube was originally developed to give mtn bikes with big wheels a compact rear triangle, while still allowing full height adjustment of a long rigid seat post .

The development of dropper seat posts, and current geometry trends have reduced some of the design’s necessity. However, it still maintains some appeal to those seeking curvaceous beauty. There is some additional triangulation, with the legs of the wishbone spreading pedal forces over the wide BB shell. The curved legs blend nicely with curved seat stays, giving an enhanced ride quality in the rear triangle.

It is certainly debatable whether any of this can be detected by the rider, some people say they can feel the difference in a curvy tubed frame, some feel no difference and prefer the moderate weight savings straight tubes can offer. Somehow, they seem to agree that steel bikes feel awesome.

Whether the appeal is form or function, the Split Seat Tube has been one of my most popular upgrades for almost two decades.

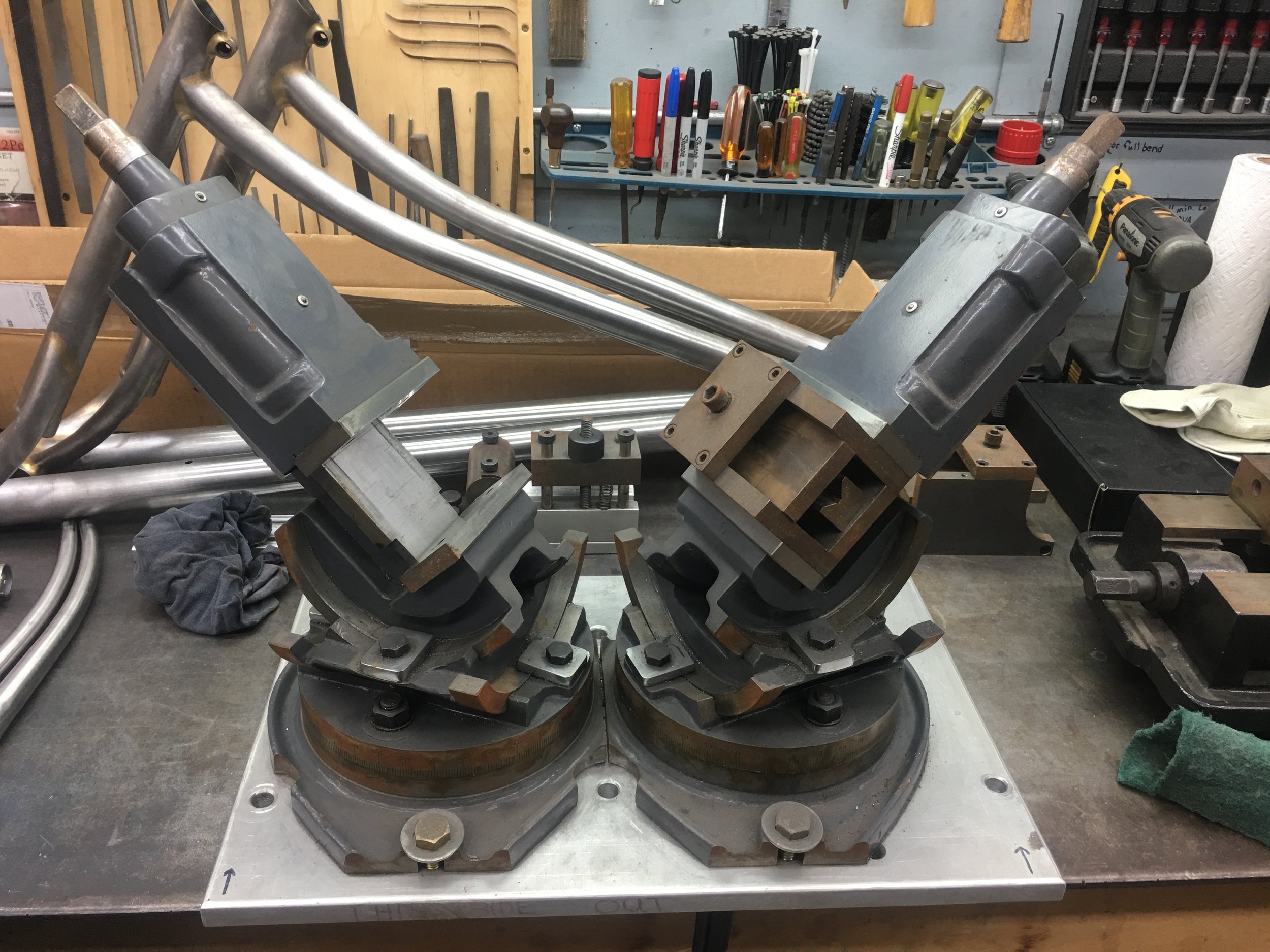

step one

Specially made braces hold a 7/8" tube in a 1 1/8" mandrel. This result a unique curve with an ovalized effect. Absolutely perfect for this application.

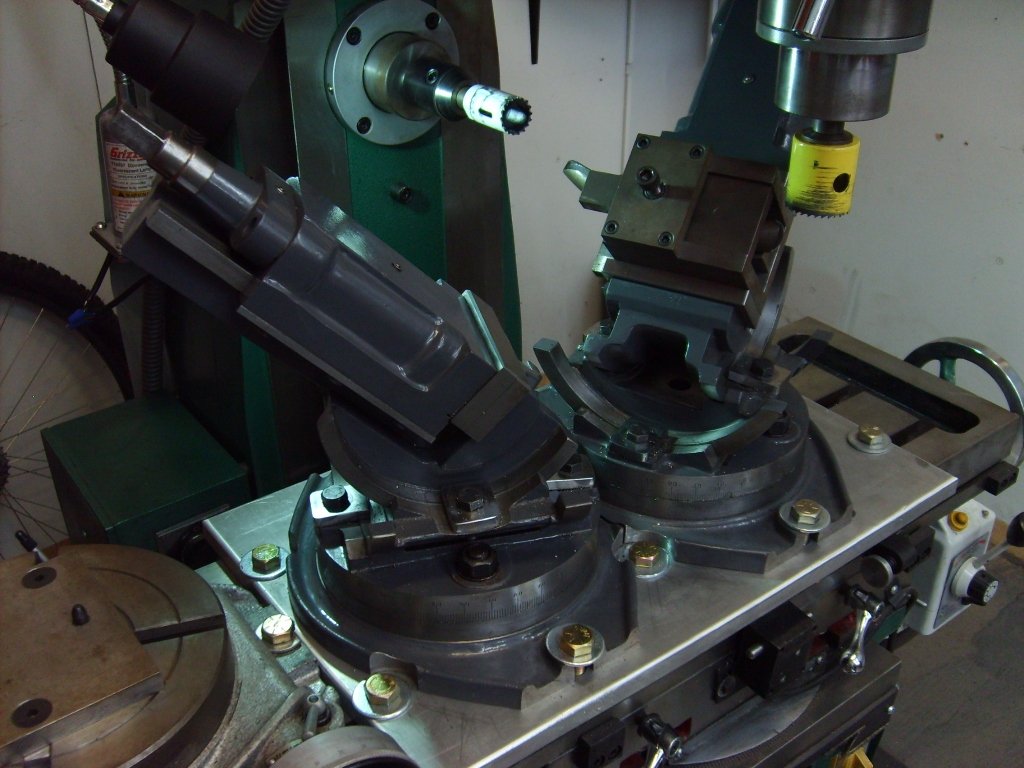

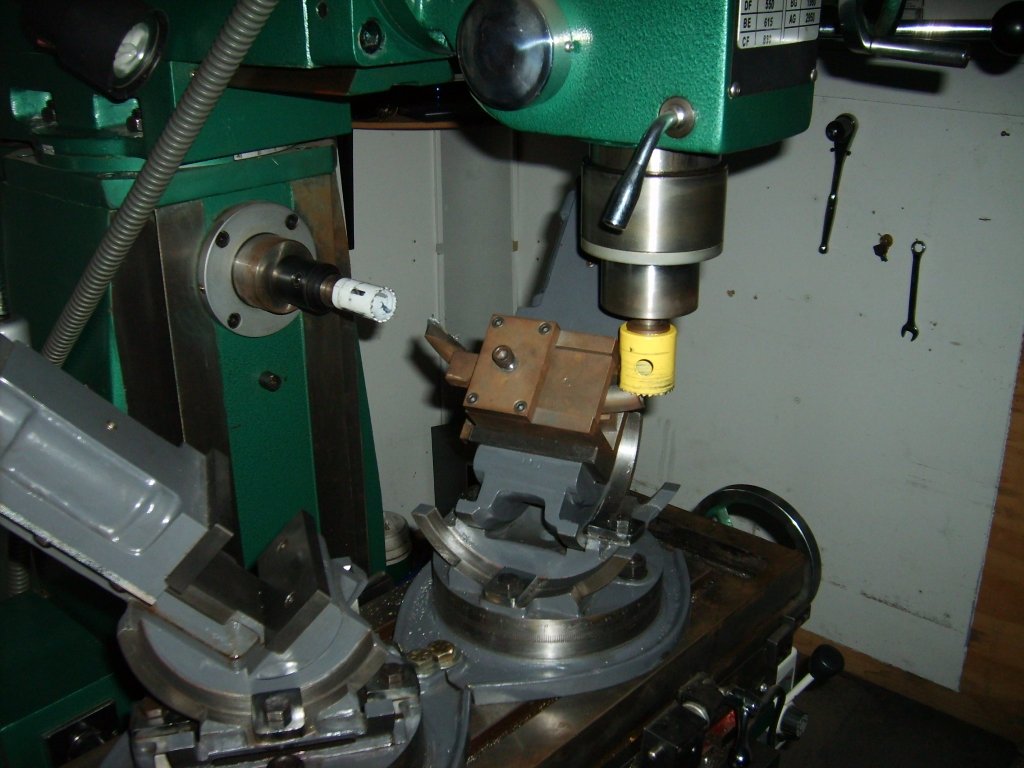

step two

A custom "miter box" from Sputnik Tool, and two 3-way adjustable machine vices to hold an exact mirror image. It works perfectly with my combo mill, which allows me to make both cuts in the same operation!

step three

The legs of the wishbone are brazed into place, then hand finished to a signature smooth transition.

step five

Final measurements are taken and the top of the wishbone is cut to exact length. Finally the seat tube lug is brazed into place and the sub-assembly is complete.

step four

The prep of the seat tube lug. This is the only machine-cut lug at Wolfhound, but they still require a fair amount of work. They feature a brazed on pinch bolt and the fine points of the “W” cut by hand with riffler files.